Assignment for week 17

- Propose a final project that integrates the range of units covered, answering:

- What will it do?

- Who's done what beforehand?

- What materials and components will be required?

- Where will they come from?

- How much will it cost?

- What parts and systems will be made?

- What processes will be used?

- What tasks need to be completed?

- What questions need to be answered?

- What is the schedule?

- How will it be evaluated?

What will it do?

My project is a Digitally fabricated bed for kids. The idea is to bulid beds for kids using digital fabrications techniques and to be easy to fabricate and assemble with low price. The bed will be look like an airplane, since it is specially desiged for my niece that has a love for flying.

Who's done what beforehand?

Companies for childern furniture

What materials and components will be required? How much will it cost? Where will they come from?

| Material | Cost |

|---|---|

| 3 MDF sheets - (16)mm | 450 EGP |

| Wood glue | 5 EGP |

| Wood paper stickers | 100 EGP |

| Plywood sheet - (30 * 50)mm^2 | 10 EGP |

| Cotton fabric | 9 EGP |

| Eboxy | 130 EGP |

| Disposable painting brush | 6 EGP |

| Diamond smooth shank nails - (25)mm | 5 EGP |

| Ball bearing - 6203z | 25 EGP |

The total cost = 740 EGP = 68$

What parts and systems will be made? What processes will be used?

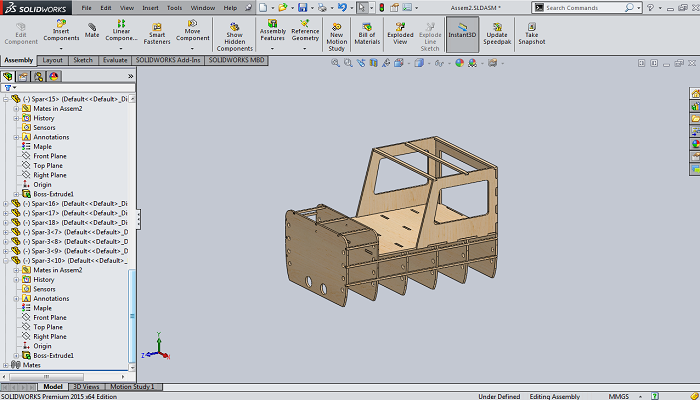

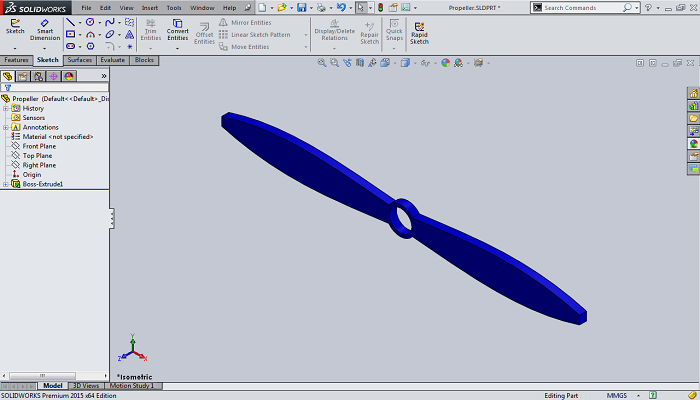

1- The Shell and Propeller

The bed's shell and propeller are designed using Solidworks and will be made from the MDF sheets and cut by CNC milling machine.

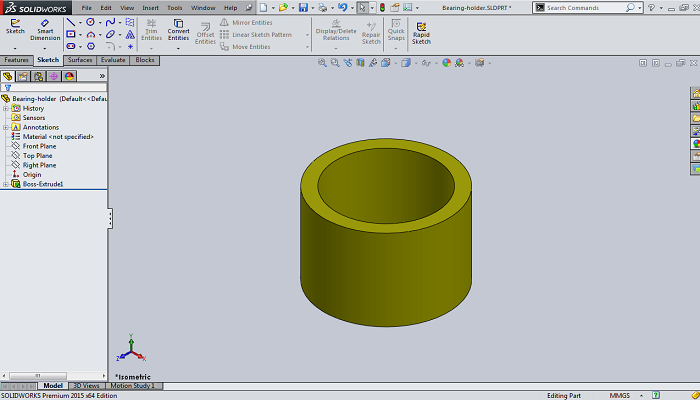

2- Mounted Ball Bearing

The mounted is designed using Solidworks and will be made from PLA using 3D printer. The ball bearing will be mounted inside it, and the propeller will be mounted from outside

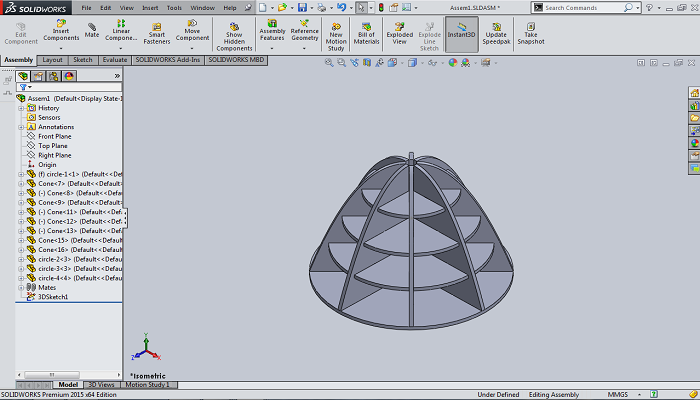

3- Nose Cone

The cone is designed using Solidworks and will be made from plywood and cut by the Laser cutter machine.

4- Assembling and Covering

The shell's parts will be fixed using press fitting technique with help of wood glue and some diamond smooth shank nails, and the covering will be made using wood paper stickers.

5- PCBs Designing and Milling

The RGB PCBs boards are designed using Eagle to add light effects to the bed, and will be milled using Roland MDX-20 Modela.

6- Composites

The cotton fabric and eboxy will be used to cover and produce a fiber composite to the nose cone.

What tasks need to be completed? What questions need to be answered?

I have already fabricated the shell and the nose cone, and I am working on the other tasks.

The question is: will the kids like the bed after it is done ?

What is the schedule?

* 4-10th June: Covering & Assembling the bed.

* 11-15th June: Casting & RGB PCB's Milling

* 20th June: Programming

* 23th June: Composties

How will it be evaluated?

* The project will be successful if :

- Combines the range of units covered.

- Digitally fabricated and assembled.

- The kids like it

This work by Joseph Gourgy is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.